Stainless Steel Capillary /coiled Tubing Applications and Advantages:

Stainless steel industrial pipes, ultra-long coiled tubings, U-shaped tubings, pressure tubes, heat exchange tubes, fluid tubes, spiral coiled tubings. Product features: high temperature steam resistance, impact corrosion resistance, ammonia corrosion resistance; anti-scaling, not easy to stain, Anti-oxidation and corrosion; long service life, reducing maintenance time, saving costs; good pipe installation technology, direct pipe replacement, safe and reliable; uniform pipe wall, wall thickness only 50-70% of copper pipe, overall thermal conductivity better than Copper tube; it is an ideal heat exchange product for the transformation of old units and the manufacture of new equipment. It can be widely used in petrochemical, electric power, nuclear industry, medicine, food and other industries.

Industrial stainless steel coiled tubings: heat exchangers, boilers, petroleum, chemicals, fertilizers, chemical fibers, pharmaceuticals, nuclear power, etc.

Stainless steel coiled tubings for fluids: beverages, beer, milk, water supply systems, medical equipment, etc.

Stainless steel coiled tubings for mechanical structures: printing and dyeing, printing, textile machinery, medical equipment, kitchen equipment, automobile and ship accessories, construction and decoration, etc.

Stainless steel bright coiled tubings: welded by stainless steel strips, then reduce the wall, reducing the wall thickness from thick to thin. This process can make the wall thickness uniform and smooth, and the reduced-wall stretched tube wall forms a weld-free effect. According to the naked eye, it is a seamless pipe, but its process is determined to be a welded pipe. The process of wall reduction is accompanied by bright annealing, so that the inner and outer walls will not form an oxide layer, and the inner and outer walls are bright and beautiful, which is really needed for medical products. The next process requires sizing, that is, the process of large and small drawing, to determine the outer diameter, the outer diameter tolerance can generally reach plus or minus 0.01mm.

Application of stainless steel coiled tubing:

1)Household

– Sinks, saucepans, washing machine drums, microwave oven liners,

razor blades etc.

2)Transport

– Exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles etc.

3)Oil and Gas

– Platform accommodation, cable trays, subsea pipelines etc.

4)Medical

– Surgical instruments, surgical implants, MRI scanners etc.

5)Food and Drink

– Catering equipment, brewing, distilling, food processing etc.

6)Water

– Water and sewage treatment, water tubing, hot water tanks etc.

7) General

– Springs, fasteners (bolts, nuts and washers), wire etc.

8)Chemical/Pharmaceutical

– Pressure vessels, process piping etc.

9)Architectural/Civil Engineering

-Cladding, handrails, door and window fittings, street furniture, structural, sections, reinforcement bar, lighting columns, lintels, masonry ,supports etc.

Standard Stainless Steel Capillary Tubing Pressure Rating and Length:

| Stainless Steel Capillary Tubing | ||||

| ITEM | Grade | Size (MM) |

Length (Mtrs) |

Pressure

(Mpa) |

| 1 | 316L 304L 304 625 825 2205 2507 | 1/8″×0.025″ | 3200 | 80 |

| 2 | 316L 304L 304 625 825 2205 2507 | 1/8″×0.035″ | 3200 | 100 |

| 3 | 316L 304L 304 625 825 2205 2507 | 1/4″×0.035″ | 2000 | 100 |

| 4 | 316L 304L 304 625 825 2205 2507 | 1/4″×0.049″ | 2000 | 100 |

| 5 | 316L 304L 304 625 825 2205 2507 | 3/8″×0.035″ | 1500 | 80 |

| 6 | 316L 304L 304 625 825 2205 2507 | 3/8″×0.049″ | 1500 | 100 |

| 7 | 316L 304L 304 625 825 2205 2507 | 1/2″×0.049″ | 1000 | 80 |

| 8 | 316L 304L 304 625 825 2205 2507 | 1/2″×0.065″ | 1000 | 100 |

| 9 | 316L 304L 304 625 825 2205 2507 | φ3mm×0.7mm | 3200 | 80 |

| 10 | 316L 304L 304 625 825 2205 2507 | φ3mm×0.9mm | 3200 | 100 |

| 11 | 316L 304L 304 625 825 2205 2507 | φ4mm×0.9mm | 3000 | 100 |

| 12 | 316L 304L 304 625 825 2205 2507 | φ4mm×1.1mm | 3000 | 100 |

| 13 | 316L 304L 304 625 825 2205 2507 | φ6mm×0.9mm | 2000 | 100 |

| 14 | 316L 304L 304 625 825 2205 2507 | φ6mm×1.1mm | 2000 | 100 |

| 15 | 316L 304L 304 625 825 2205 2507 | φ8mm×1mm | 1800 | 80 |

| 16 | 316L 304L 304 625 825 2205 2507 | φ8mm×1.2mm | 1800 | 100 |

| 17 | 316L 304L 304 625 825 2205 2507 | φ10mm×1mm | 1500 | 70 |

| 18 | 316L 304L 304 625 825 2205 2507 | φ10mm×1.2mm | 1500 | 70 |

| 19 | 316L 304L 304 625 825 2205 2507 | φ10mm×2mm | 500 | 100 |

| 20 | 316L 304L 304 625 825 2205 2507 | φ12mm×1.5mm | 500 | 80 |

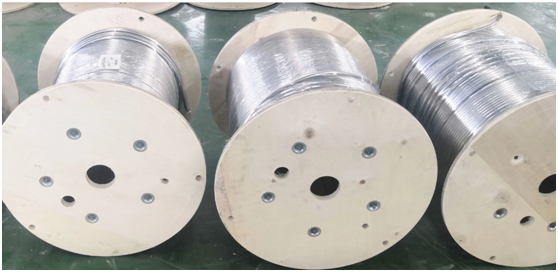

Below are photos for Stainless Steel coiled tubings/capillary tubings Projects: